Blister packaging is a widely used packaging solution that provides both protection and attractive product presentation. It involves sealing a product between a transparent plastic blister and a cardboard backing. This method offers several advantages, making it a popular choice for various industries. In this article, we will explore the benefits of blister packaging, discuss different types of blister packaging, and highlight Uno Plast, a leading company in providing blister packaging solutions.

What is Blister Packaging

Blister packaging is a type of packaging that involves sealing a product between a transparent plastic blister and a cardboard backing. This packaging method is commonly used across industries due to its ability to showcase products while providing them with adequate protection. It is particularly effective for small items like pharmaceutical products, electronics, consumer goods, and food items.

Advantages of Blister Packaging

Blister packaging offers several advantages for both manufacturers and consumers. Let’s take a closer look at some of its key benefits:

Enhanced product visibility: Blister packaging allows customers to see the product clearly, which can positively influence their purchasing decisions. The transparent plastic blister provides a clear view of the product, its features, and any branding elements.

Increased product shelf life: Blister packaging provides excellent protection against external factors such as moisture, light, and air. This extended shelf life helps preserve the product’s quality and reduces the risk of spoilage or damage.

Protection against tampering: Blister packaging can incorporate tamper-evident features, such as heat-sealed blister packs. This ensures that the product remains secure and tamper-free, assuring customers of its authenticity and safety.

Cost-effective packaging solution: Blister packaging is cost-effective compared to other packaging methods. It requires fewer materials and can be easily produced in large quantities, reducing overall packaging costs.

Customizable designs for brand promotion: Blister packaging offers ample space for branding and product information. Manufacturers can customize the cardboard backing with eye-catching designs, logos, and product details, effectively promoting their brand and attracting customers’ attention.

Types of Blister Packaging

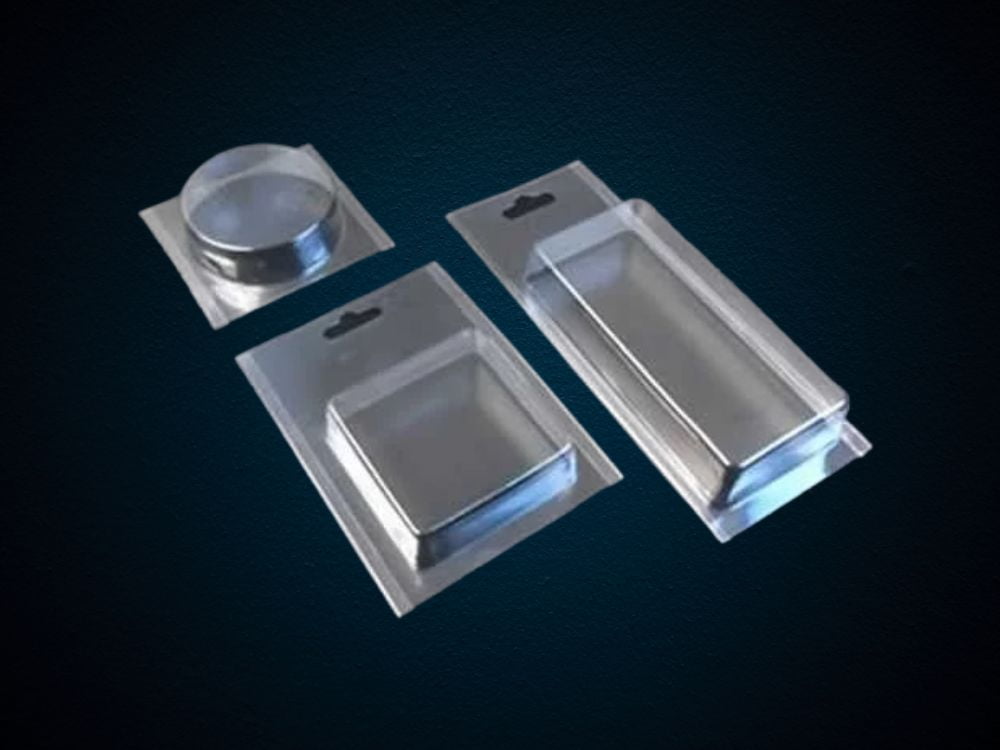

Blister packaging comes in various types, each suited for different products and requirements. Some common types include:

Face Seal Blister Packaging: In this type, the product is sealed between a plastic blister and a printed cardboard backing. The blister is heat-sealed to the cardboard, providing a secure enclosure.

Trapped Blister Packaging: Trapped blister packaging consists of a plastic blister that is trapped between two layers of cardboard. This design offers enhanced protection and rigidity.

Mock Clamshell Blister Packaging: Mock clamshell packaging resembles a clamshell shape without actually having a hinge. It provides easy access to the product while maintaining its visibility and protection.

Blister Packaging Process

The blister packaging process involves several stages to ensure the production of high-quality packages. Here is an overview of the typical process:

Material selection: Uno Plast carefully selects the appropriate materials for blister packaging, considering factors such as product requirements, durability, and environmental impact.

Design and prototyping: Uno Plast collaborates with clients to develop customized packaging designs that align with their branding and product specifications. Prototypes are created and evaluated before moving forward.

Forming and sealing: The plastic blister is formed using specialized equipment, and the product is placed inside. The blister is then sealed to the cardboard backing using heat or other sealing methods, ensuring a secure enclosure.

Quality control measures: Uno Plast maintains strict quality control throughout the blister packaging process. Each package undergoes rigorous inspections to ensure it meets the highest standards of quality and functionality.

Blister Packaging Industries

Blister packaging finds applications in various industries due to its versatility and effectiveness. Let’s explore some industries that extensively utilize blister packaging:

Pharmaceutical industry: Blister packaging is widely used in the pharmaceutical sector for packaging tablets, capsules, and other medication. It ensures proper dosage control, product protection, and ease of use for consumers.

Electronics industry: Electronics components and devices are often packaged in blister packs to provide protection during transportation and display. Blister packaging offers visibility and safeguards delicate electronic items.

Consumer goods industry: Many consumer goods, such as small toys, stationery items, cosmetics, and personal care products, are packaged using blister packaging. It allows customers to see the product clearly before making a purchase decision.

Food and beverage industry: Blister packaging plays a crucial role in packaging individual food items like chocolates, mints, and gums. It maintains product freshness, extends shelf life, and provides an attractive presentation on store shelves.

Factors to Consider when Choosing Blister Packaging

When selecting blister packaging for your products, it’s important to consider several factors. These include:

Product requirements: Evaluate the size, shape, and fragility of your product to determine the appropriate blister packaging design and materials.

Regulatory compliance: Ensure that the chosen blister packaging meets all relevant industry and regulatory standards, such as child-resistant packaging requirements for pharmaceuticals.

Packaging cost: Consider your budget and packaging cost constraints while selecting the most suitable blister packaging solution.

Market appeal and branding opportunities: Blister packaging provides an opportunity to showcase your brand and enhance product visibility. Choose a design that aligns with your brand image and attracts customers.

Advancements in Blister Packaging Technology

Blister packaging continues to evolve with technological advancements, offering innovative features to further enhance product safety, convenience, and customization. Here are some notable advancements in blister packaging technology:

Intelligent Blister Packaging: This incorporates smart features such as temperature monitoring, humidity control, or RFID (radio-frequency identification) tags to track product information and ensure optimal storage conditions.

Child-Resistant Blister Packaging: It includes specialized mechanisms that make it challenging for young children to open the package, reducing the risk of accidental ingestion or exposure to potentially harmful products.

Anti-Counterfeit Features: To combat counterfeit products, blister packaging can incorporate anti-counterfeit measures such as holograms, QR codes, or unique identifiers that allow consumers and retailers to verify the authenticity of the product.

Interactive Blister Packaging: Interactive blister packaging engages consumers through augmented reality (AR) or QR codes, providing additional product information, usage instructions, or interactive experiences that enhance brand engagement.

Future Trends in Blister Packaging

The blister packaging industry is constantly evolving to meet changing market demands and consumer preferences. Here are some future trends to watch out for:

Eco-friendly materials: With increasing environmental awareness, there is a growing demand for blister packaging made from sustainable and recyclable materials. Manufacturers are exploring options such as biodegradable plastics and plant-based materials.

Smart packaging technologies: Integration of smart technologies, such as RFID tags or NFC chips, into blister packaging can enable features like product tracking, authentication, and interactive customer experiences.

Customized packaging experiences: Personalization is gaining prominence, and blister packaging is no exception. Future trends involve incorporating customization options, such as personalized graphics or interactive elements, to create a unique packaging experience for customers.

Blister packaging is a versatile and effective packaging solution that enhances product presentation while providing protection against external elements. Its advantages, such as improved product visibility, extended shelf life, and cost-effectiveness, make it a popular choice across industries. Uno Plast, a leader in blister packaging solutions, offers quality products, innovative designs, and sustainable packaging options. When choosing blister packaging, consider factors like product requirements, regulatory compliance, packaging cost, and branding opportunities. As the industry continues to evolve, future trends in blister packaging include eco-friendly materials, smart packaging technologies, and customized packaging experiences.

Explore our blister packaging range

4 Responses

Keep sharing information like this, it would be great if you can write a blog post for Automotive Industry

I can’t thank the author enough for this enlightening article. The positivity and optimism conveyed throughout have left me feeling motivated and uplifted.

A truly delightful read! The positive approach of this article is infectious, and it left me with a smile on my face. Blister Packaging is future.

Thank You NN Hydraulic